On a ship there are many parameters that needs to be controlled or

monitored including: temperatures, pressure, level, viscosity, flow

control, position of vessel, speed, torque control, voltage, current,

machinery status (on/ off), and equipment status (open/ closed).

As the market is driving ship owners to become more efficient with

reduced staff on board it called for an automatic control and monitoring

system for the ship that enabled unattended operation of machinery

spaces. Vessels capable of safe operation at any period of time qualify

as UMS (Unattended Machinery Space) ships.

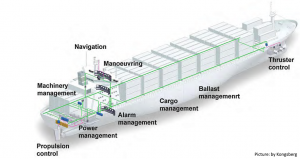

A modern automation and control system is a fully integrated systems

covering many aspects of the ship operation that includes the propulsion

plant operation, power management operation on the auxiliary engines,

auxiliary machinery operation, cargo on-and-off-loading operation,

navigation and administration of maintenance and purchasing of spares.

Propulsion (Main Engine) and Power (AuxiliaryEngines) Monitoring & Control

Monitoring and control of the ships propulsion and power is essential

for its efficiency and safety and there are many systems and parameters

to consider like: fuel consumption, combustion temperature, engine

temperature, diesel engine safety and start/stop, generator voltage and

frequency control, generator load in KW and %, load control, torque,

heavy consumers logic, control of diesel electric propulsion, thrusters

monitoring and control etc..

Automatic control of the starting of the main

engine can be done from the bridge as well as in Engine control room.

The automatic controls employed in starting the engine is by the

following sequence:

- Automatic control used in correctly positioning of the cam shaft.

- Admitting starting air

- Admitting fuel

- Starting air shut off

- Speed adjustment to the value required

Thus

the engine is started and the various parameters like temperature,

pressure, flow and tank level have to measured at every watch to make

sure that the engine is running safely.

Temperatures of lube oil, JCW, exhaust gas, etc. are measured.

Pressures of lube oil, JCW, fuel oil, and starting air etc. are measured.

Flow of fuel oil is measured while running.

Tank levels of Heavy fuel oil, diesel oil, and lube oil are measured.

For measuring the parameters we make use of the transducers, in turn sending the input signal to the automatic control system.

Auxiliary Machinery Monitoring and Control

Auxiliary machinery monitoring and control covers several systems

like: main sea & fresh water cooling system – pumps, system

pressure, temp. etc., Potable and fresh water control, Air compressors,

Bilge & sludge control – Tank level, pumps, Fuel oil system – Tank

levels, temp., viscosity, flow, purifiers, heaters etc., Other cooling

systems, Boiler/steam system – pumps, valves, pressure temp. etc., Air

Conditioning, ballast water treatment, exhaust gas treatment equipment.

This is employed in automatic starting and stopping of the auxiliary

generator from the engine control room. So of the automatic control used

are:

- Starting and stopping of the engine according to the load demand.

- Synchronization of incoming generator.

- Closing the circuit breaker

- Load sharing between the alternators

- Maintaining the supply frequency and voltage.

- Engine and alternator fault protection

- Preferential tripping of non-essential loads.

Cargo & Ballast Monitoring & Control

For safe on and off loading of cargo, especially on tankers, this

process is closely monitored and many times incorporates functions

like: Level gauging, Control of cargo pumps, Valve control, Ballast

& ballast pump control, Heeling control, Remote monitoring of

temperature, pressure, and flow.

Condition based monitoring

In order to further improve the ships efficiency many equipment

manufacturers are looking into feeding the main control and monitoring

system with opportunities for condition based monitoring. This would

further improve the possibilities of preventing breakdowns on board.

No comments:

Post a Comment